CNC Precision Parts Factory: Innovating Metal Fabrication Solutions

In today's competitive landscape, the role of a CNC precision parts factory has never been more critical. With advancements in technology and the increasing demand for precision-engineered components, industries across the board are relying on these specialized manufacturers to meet their unique needs. This article delves deep into the operations, benefits, and future of CNC precision parts factories, showcasing how companies like deepmould.net are leading the charge in metal fabrication.

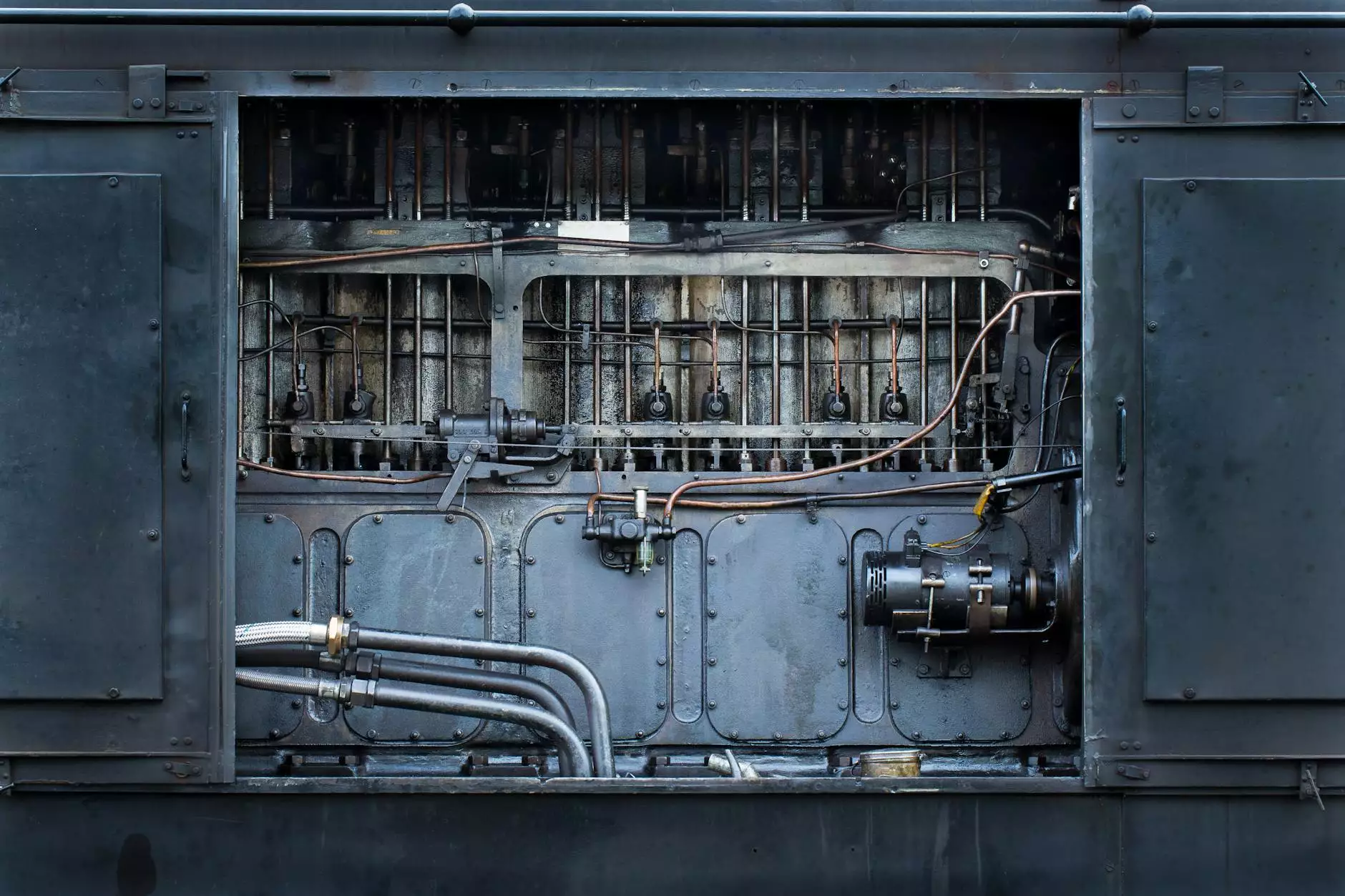

The Essence of CNC Precision Machining

CNC, or Computer Numerical Control, machining refers to the automated control of machine tools via computers. CNC precision parts factories utilize this advanced technology to produce high-quality, intricate parts with remarkable accuracy. Here's how it works:

- Design Input: The process begins with a CAD (Computer-Aided Design) file that outlines the component specifications.

- Tool Path Generation: The CNC software converts the CAD design into a series of commands that guide the machine.

- Machining Process: The machine uses various tools to cut, drill, or grind the material according to the programmed instructions.

- Quality Control: Once manufacturing is complete, each part undergoes rigorous inspection to ensure it meets the specified tolerances.

Benefits of Utilizing a CNC Precision Parts Factory

Choosing a reliable CNC precision parts factory offers several significant advantages:

1. Unmatched Precision and Accuracy

When it comes to manufacturing parts, precision is paramount. CNC machines operate with a degree of accuracy that is difficult for human-operated machinery to match. This ensures that each component produced meets the exact specifications required, minimizing material waste and rework.

2. Efficiency and Speed

Modern CNC machinery enables rapid production due to its automated processes. This efficiency correlates directly to shorter lead times and faster delivery of products, which is essential for businesses needing quick turnaround times.

3. Flexibility in Design

CNC technology supports a wide range of materials, including metals, plastics, and composites. It allows for the easy creation of complex geometries and designs that traditional manufacturing methods cannot achieve.

4. Scalability

A CNC precision parts factory can easily scale its operations to meet demand. Whether it's a small batch of custom parts or a large production run, CNC machining can adapt without compromising quality.

5. Cost-Effectiveness

While the initial investment in CNC technology may be higher, the long-term savings realized through efficient machine operation and reduced material waste make CNC machining a cost-effective choice for many businesses.

Industries That Benefit from CNC Precision Parts Factories

The versatility of CNC machining makes it a vital resource across numerous sectors. Here are some industries that significantly benefit from the expertise of CNC precision parts factories:

- Aerospace: The aerospace industry requires components that meet stringent safety and performance standards. CNC machining allows for the production of lightweight yet robust parts.

- Automotive: CNC precision parts factories play a crucial role in the automotive sector by providing high-performance components that enhance vehicle efficiency and safety.

- Medical Devices: Precision is essential in medical device manufacturing. CNC machining facilitates the production of intricate, reliable components crucial for patient care.

- Electronics: From housings to connectors, the electronics industry relies on CNC manufacturing for components that support the rapid technological evolution.

- Consumer Products: Many consumer products are fabricated using CNC techniques, including custom designs that meet specific market demands.

Choosing the Right CNC Precision Parts Factory

Selecting the right CNC precision parts factory is critical to your project's success. Here are some factors to consider:

1. Experience and Expertise

Identify manufacturers with a proven track record in your industry. Their experience can significantly impact the quality and efficiency of your project.

2. Technology and Equipment

Examine the machinery and technologies used by the factory. Advanced CNC machines with the latest software capabilities will deliver superior precision and flexibility.

3. Quality Assurance Processes

Look for factories that implement stringent quality control measures. Certifications such as ISO 9001 indicate a commitment to maintaining high-quality standards.

4. Customization Capabilities

Your parts may require specific designs and tolerances. Ensure the factory can accommodate custom requests effectively.

5. Customer Support

Responsive and knowledgeable customer support is crucial throughout the manufacturing process, from initial inquiries to post-production support.

The Future of CNC Precision Parts Factories

As technology continues to evolve, CNC precision parts factories are poised for exciting advancements. Key trends include:

- Increased Automation: With the rise of smart factories and Industry 4.0, we can expect further automation in CNC operations, enhancing efficiency while reducing human error.

- 3D Printing Integration: Combining CNC machining with additive manufacturing techniques will allow factories to produce complex parts more efficiently.

- Sustainability Initiatives: Increased focus on eco-friendly manufacturing practices will lead CNC precision parts factories to adopt more sustainable materials and techniques.

- Advanced Materials: As new materials are developed, CNC machining capabilities will expand to accommodate these innovations.

- Global Collaboration: Enhanced communication technologies will facilitate greater collaboration between global partners, streamlining supply chains and production processes.

Conclusion

In conclusion, the CNC precision parts factory stands at the forefront of modern manufacturing. By harnessing advanced technology, CNC factories deliver unparalleled precision and efficiency, transforming industries from aerospace to consumer products. Companies like deepmould.net exemplify the potential of CNC machining, leading the way in innovation and quality. As we look to the future, the evolution of these factories promises exciting advancements that will shape the landscape of manufacturing for years to come.

Investing in a reputable CNC precision parts factory is not just a decision for today; it's a step toward a more efficient, innovative, and competitive future. Embrace the possibilities of CNC machining and unlock your business's potential.